We can provide the Speaker Accessories

Speaker Grill & Mesh, Metal Corner Feet

Speaker terminal board plastic corner steel handle speaker grill

Metal corner air hole steel handle top handle

Our material-neutral approach means that each solution is developed in response to specific customer needs, while striving to maximise cost-effectiveness.

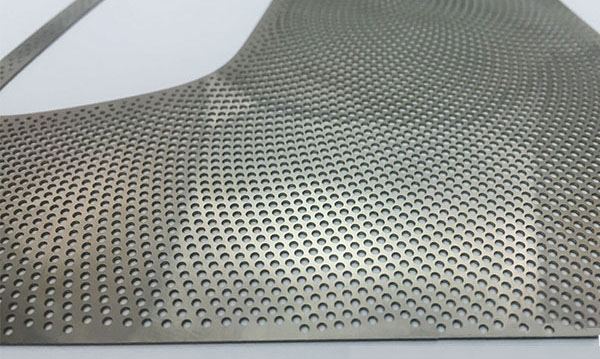

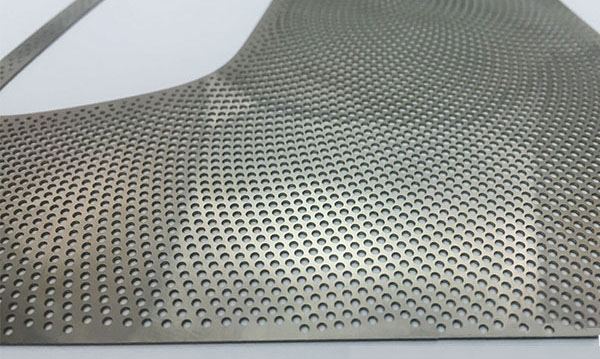

Material: Mild steel sheet, stainless steel sheet, monel sheet, copper sheet, brass sheet, aluminum sheet

Thickness: 0.1-3mm

Hole pattern: Round, square, hexagonal, scale, rectangular, triangle, cross, slotted

Hole diameter: 0.8-10mm

Standard plate size: 1m× 2m, 3× 8, 4× 8, 3× 10, 4× 10

Processing: Mold, piercing, cutting, cutting edge, leveling, clean, surface treatment

Application: Used for oil filters as fencing screen for expressway, railway and other construction facilities used in workshops as well as other constructions as sound isolation sheet decorative sheet for stairs, environmental tables and chairs sifting in grains, feed and mines also used in making of kitchenware such as fruit basket, food cover

A, Machines

B, Product Photos

C, Office and Warehouse

|

|

|

Term |

Specification |

|

1.Material |

Stainless steel

304/304L201/316/316L |

Aluminum/pure Al/

alloy Aluminum |

Mild/ Iron steel |

Galv.steel/

Gal.30/40/60/90 |

PVC |

Others |

|

2.Hole shape |

Round, square, slot, diamond, triangle, hexagonal, clover, others |

3. Dimensions (mm)

(length*width*thickness) |

1) hot-rolled coil

2) Perforated sheet

Length: within 2500

Width within: 1250

Thickness within 5mm |

|

4.Hole dia*pitch(mm) |

Customized, such as: 5*10, 3*5, 10*15, etc |

|

5. Perforated pattern |

straight |

Staggered: 45 degree, 60 degree |

|

6.Fabrication |

bended |

coiled |

others |

|

7.Margin |

No margin |

Common margin |

Customized Requirement |

|

8. Open area |

20% |

40% |

60% |

Others |

|

9.Surface treatment |

Powder coated |

Galvanized |

|

|

Processing parameters in photo chemical machining are primarily dictated by the gauge of the material to be etched. The typical feature size tolerance is± 10% material thickness. Through holes and slots must normally be specified at 1 to 1.2 times material thickness. Outside and inside radii will typically run at one half material thickness. Center-to-center dimensions and other geometrically toleranced dimension such as true position or parallelism that are derived directly form the photo-tool may be specified at .0001".

Processing parameters in photo chemical machining are primarily dictated by the gauge of the material to be etched. The typical feature size tolerance is± 10% material thickness. Through holes and slots must normally be specified at 1 to 1.2 times material thickness. Outside and inside radii will typically run at one half material thickness. Center-to-center dimensions and other geometrically toleranced dimension such as true position or parallelism that are derived directly form the photo-tool may be specified at .0001".

We are committed to distinguishing ourselves by supplying you with excellent parts and superior customer service. When requested we will gladly recommend ways to improve your parts and reduce the cost of producing them.

For more information Click Here